RECIPROCATING COMPRESSORS

development of reciprocating compressors:

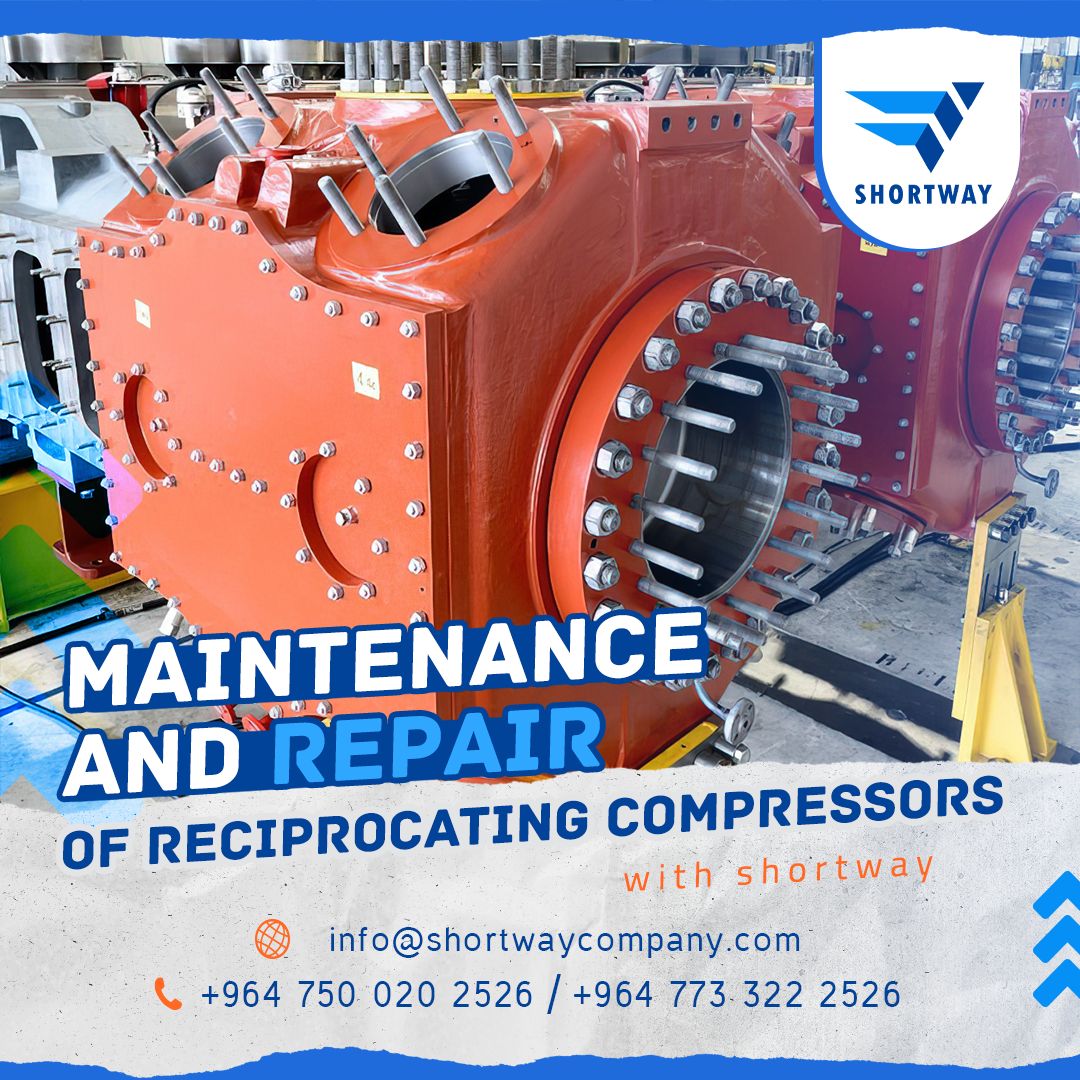

Reciprocating compressors are a pivotal means for efficiency and sustainability across various industries. These precise systems necessitate regular maintenance to ensure optimal performance and prevent wear and breakdowns.

Routine maintenance steps for reciprocating compressors encompass thorough inspection of mechanical and electrical components, emphasizing lubrication of parts and replacement of worn components. Monitoring pressure levels and temperatures is imperative to preserve compressor performance and mitigate potential damage.

On the other hand, advancing reciprocating compressors involves embracing modern and sophisticated techniques. This includes updates in component design to enhance compressor efficiency and reduce energy consumption. Embracing smart control systems and sensor technology for precise performance monitoring and predictive maintenance is encouraged.

Through continuous improvement and effective maintenance, reliable operation and sustainable efficiency can be achieved for reciprocating compressors, contributing significantly to productivity and sustainability goals across diverse industries

Reciprocating compressors represent a cornerstone in numerous industrial applications, offering efficient compression of gases across a spectrum of operations. Effective maintenance of these sophisticated systems is imperative to ensure their longevity, and optimal functionality, and prevent operational disruptions.

Routine maintenance involves comprehensively assessing the compressor’s mechanical and electrical components. This includes meticulous checks of piston rings, valves, cylinders, and lubrication systems. Regular lubrication ensures smooth operation while meticulous examination helps identify and replace worn-out parts, mitigating potential failures.

Developments in reciprocating compressors center around enhancing performance and energy efficiency. Advancements in material science lead to the creation of robust components capable of withstanding extreme conditions while reducing friction and energy loss. Moreover, precision engineering and design modifications aim to minimize leakages, optimize compression ratios, and improve overall system efficiency.

Integrating smart technologies, such as IoT sensors and predictive analytics, further revolutionizes maintenance strategies. Real-time monitoring allows for the proactive identification of potential issues, enabling predictive maintenance interventions and preventing costly downtime.

Continuous advancements in reciprocating compressors aim not only to improve performance but also to align with environmental sustainability goals. Efforts are directed toward reducing emissions, enhancing energy efficiency, and adopting eco-friendly refrigerants, aligning with global initiatives for a greener future.

In conclusion, the ongoing evolution of reciprocating compressors relies on a robust maintenance regimen and innovation-driven development. This synergy ensures not only reliable operations but also aligns with the ever-evolving demands for efficiency, sustainability, and environmental stewardship in the industrial landscape